IS YOUR ELECTRICAL PANEL DANGEROUS? WHAT YOU NEED TO KNOW

Is Your Panel or Breaker Box A Fire Hazard?

Electric Panel Fire Risk Assessment

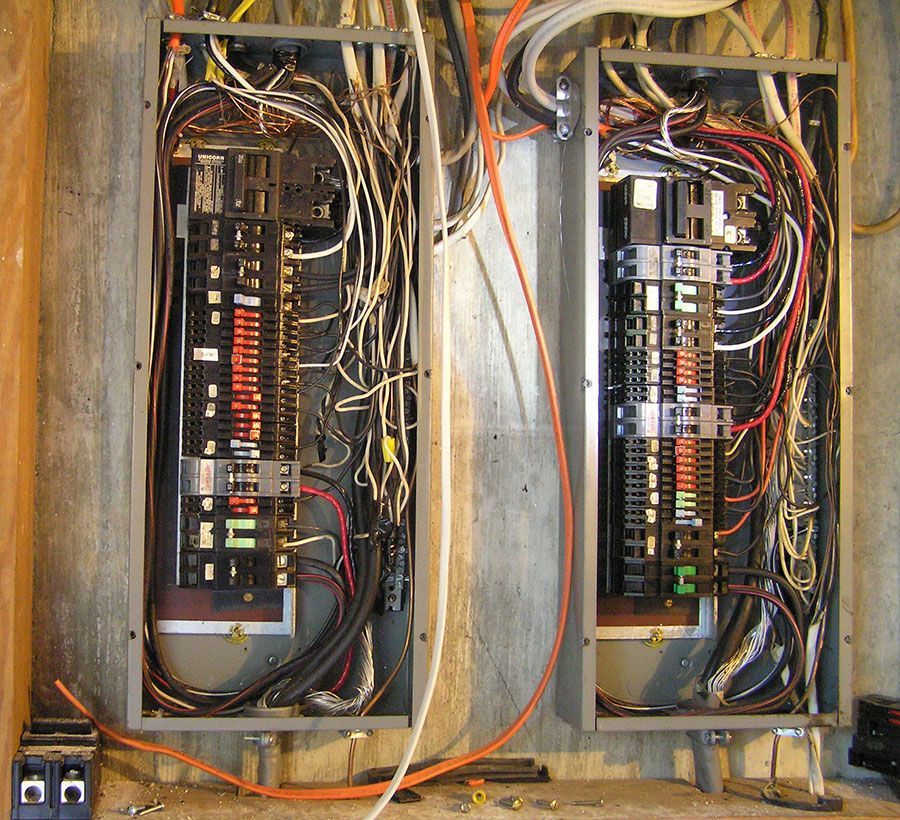

Inspect your electrical panel closely. If any labels within it bear the name "Zinsco," your risk of fire could be elevated. These older panels do not meet today's UL (Underwriters Laboratories) standards and would not pass modern safety requirements.

Identified Zinsco design flaws linked to fires include:

- Unsecured connection between breakers and the bus bar, which delivers power to circuits.

- Incorporation of certain components made of aluminum, which has a lifespan of around 30 years.

- Presence of an easily corroded bus bar.

- Potential for the panel to conduct power even when the breaker seems off.

Historical Context

During the 1970s, Zinsco panels were commonly installed in new buildings, particularly in the Western United States. Following Zinsco's acquisition by GTE Sylvania in 1973, panels continued to bear the Zinsco name in some form. However, Zinsco breaker production ceased in the mid-70s.

Recognized Risk

Zinsco breakers exhibit a manufacturing defect that could lead to higher failure rates. While these panels may have functioned well in the past, modern buildings' higher energy demands could exacerbate their vulnerability. Notably, Zinsco breakers utilize an aluminum clip shaped like a horseshoe to connect each breaker to the bus bar. However, this clip lacks an effective mechanism to maintain a secure connection to the bus bar. Zinsco panels might feature either an aluminum or copper bus bar. Over time, the aluminum clip's expansion and contraction due to heat could compromise its contact with the bus bar, resulting in "arcing." If an aluminum bus bar is present, corrosion may occur, leading to poor connections and arcing. Arcing can cause a "welding effect" that melts the breaker's metal and plastic construction. This could trigger a chain reaction, potentially leading to panel fires or sparks.

Melting Breaker Hazard

A breaker might melt onto a panel's bus bar, losing its ability to trip during overcurrents or short circuits. This can result in an influx of excessive power from the external electrical supply, leading to an inability to manually stop or shut off electricity flow. The continued flow could cause wires to melt, creating a risk of panel overheating and fires.

Response for Zinsco Panel Owners

Detecting damaged or failing Zinsco breakers is not straightforward through visual inspection alone. Engage a licensed electrical contractor to evaluate your panel. A reliable electrician should offer a complimentary safety analysis. Given the inherent design flaws, all Zinsco breakers/panels should be replaced with up-to-date, UL-listed equipment.

Early Detection's Role in Fire Prevention

In a case at an assisted living facility, an infrared thermal camera identified a Zinsco panel with temperatures exceeding 20 degrees above ambient levels. Such readings indicate potential hazards, prompting the recommendation for an electrician's assessment and panel replacement.

Identifying Zinsco Panels

Search your electrical panel for labels including:

- Zinsco

- Sylvania

- Sylvania-Zinsco

- GTE-Sylvania

Manufacturers/vendors of Zinsco-style circuit breakers encompass:

- Challenger, Challenger Electric

- Connecticut Electric (Unique Breakers, Inc. or UBI)

- GTE Electric

- Kearney Electric

- Millbank Electric

- Thomas & Betts Electric

Note that black breakers can also be Zinsco, despite the presence of bright blue, red, and green tabs on individual breakers within the panel. If you discover or suspect that your breaker box or electrical panel is a Zinsco Panel - Contact Us Immediately to replace! This is an URGENT Matter that needs to be resolved for the safety of you and your home.

Share On: